Inventory Management

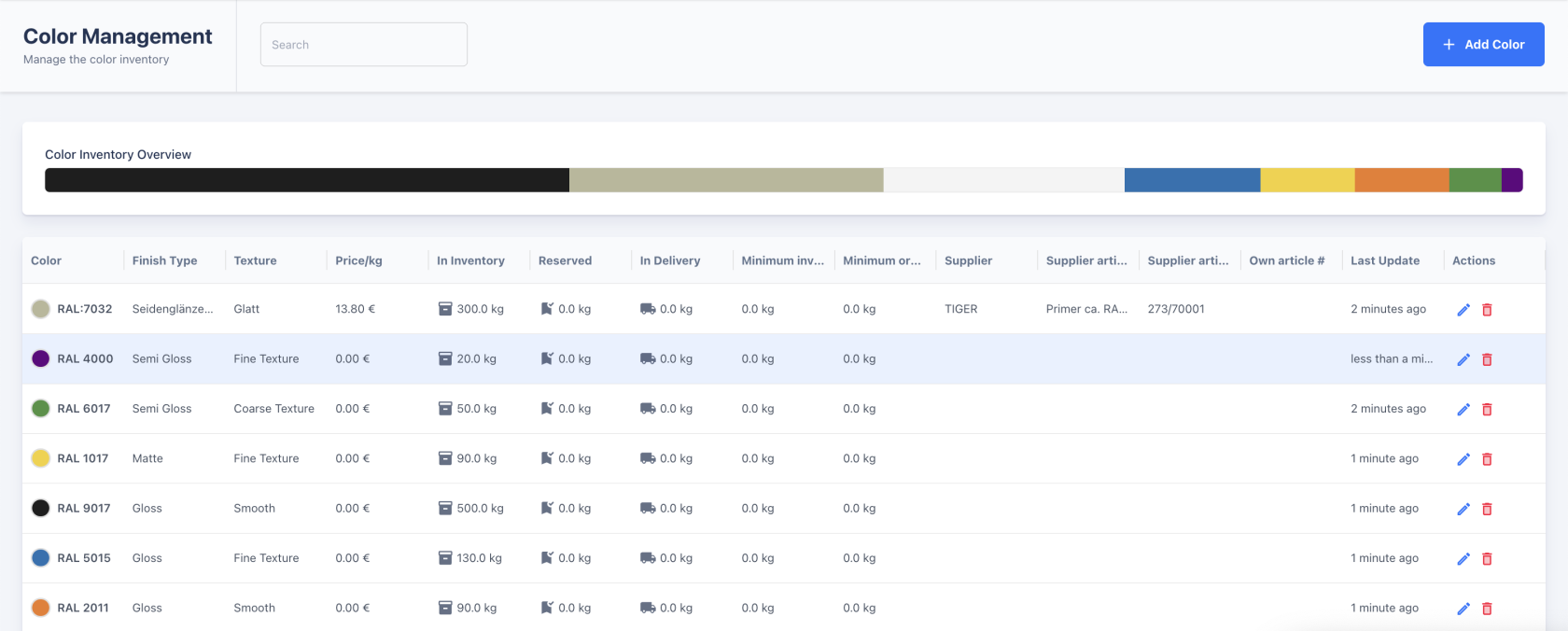

The inventory management in Surface Solutions is the central tool for maintaining, monitoring, and organizing all materials and colors used in your company. It ensures that materials are always available, correctly calculated, and that stock levels are managed transparently and efficiently.

With inventory management, you can:

-

Create and manage new materials and colors

-

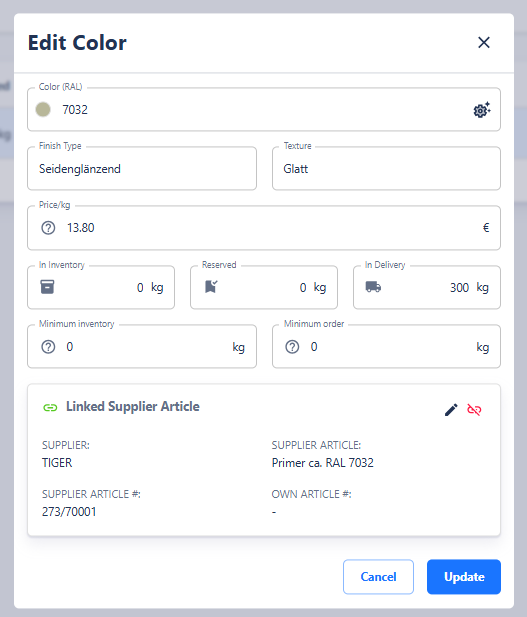

Edit article information, including name, gloss level, surface structure, and price per kilogram

-

Monitor stock levels, manage reserved quantities, and incoming deliveries

-

Set minimum stock levels and minimum order quantities to avoid shortages

-

Link articles with supplier information and preferred order settings

Stock Levels and Calculation

The available stock of an article is automatically calculated using the following formula:

Available Stock = Stock - Reserved Quantity + Quantity in Delivery

-

Stock: Quantity physically available in the warehouse

-

Reserved Quantity: Quantities already allocated for orders and therefore not available for new orders or purchases

-

Quantity in Delivery: Quantities that have been ordered but have not yet arrived in the warehouse

If the available stock falls below the defined minimum stock level, the article is automatically added to the requirements list. This ensures that materials can be repurchased in time.

Reservations and Deliveries

-

As soon as a purchase is created or material requirements are added, the corresponding quantities are automatically marked as reserved and deducted from the available stock.

-

Incoming deliveries automatically increase the stock levels.

-

This calculation ensures that stock levels always reflect the current material flow correctly and prevents double reservations.

Purchase Optimization

Inventory management is closely linked with the requirements list. Based on current stock levels, reserved quantities, and deliveries, the system automatically generates purchase suggestions that meet material requirements while minimizing costs. Articles of the same color are grouped to make purchasing as efficient as possible.

Through this automated calculation and monitoring of stock levels, inventory management provides a central solution to plan materials optimally, avoid shortages, and optimize purchasing costs.